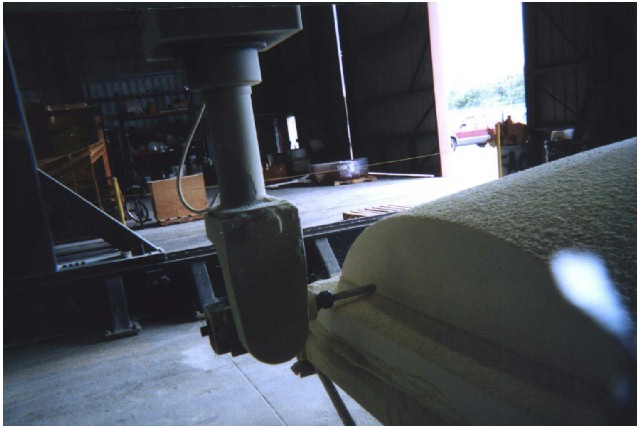

The stern of the plug with me at the controls of the Vectorworks #2 CNC router. They mill plugs for 180' yachts in the Titisville facility.

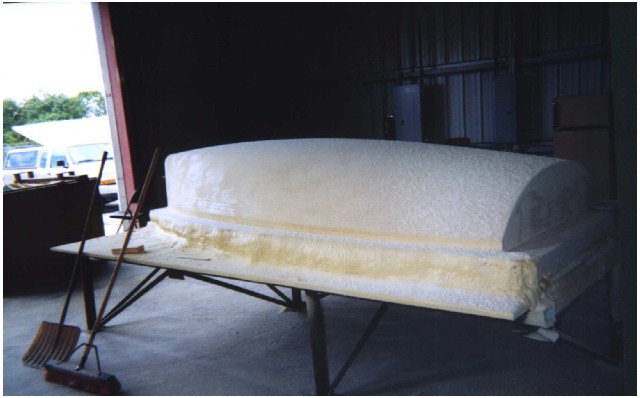

Here are a few pictures of the moth we are building a plug for. The original boat was a joint effort between Paul Lindenberg and I (unfortunately, Paul moved about an hour and a half away and is currently not participating in this project). We first took a toy double ender and wacked off one end. We then decided to plumb up the bow some and widen the transom. We made a 22Ē plug and sawed it into 10 equal pieces. I took off the lines and offset them in a table offset. Paul lofted the waterlines and we drew the stations from them. Then I lofted the Diagonals and buttock lines and drew up a set of frames. I then did it again and came up with the very fair hull you see in our first set of photos. We build Paulís boat exactly as I drew it, but I didnít like the sheer, bow fullness, stem and last two stations at the transom. I raked the stem forward about 7/8th of an inch, took the first three frames out in the area of the keel to about 5 inches up the side. I just let them float; this removed a hard spot in the bow region. I dropped the sheer at the transom one inch and raised it one inch in the front. It is a much prettier boat than the first hull. However, the first hull has a waterline that is about 1 1/8Ē longer than the second does.

Now the plug I am milling here is the second change from the second wooden hull. The main differences are a much finer entry than the second wood hull and much much finer than the first one with the hard spot. My wood boat has a displacement of about 245 lbs while Paulís only displaces approximately 225 lbs. The forth design comes in at 322. The configuration allows a heavier skipper to be competitive but at the same time, with a lighter skipper the hull lifts considerable wetted surface out of the water, but still very nearly maintains the full water line length fore and aft. We are going to mill a deck plug and plan on making four different versions:

1. The Classic Moth. It will have option of glass or wood board and rudder. All will come with Carbon Spars. We will offer this as a bare hull kit up to a finished boat ready to sail. If anyone is interested we will offer a centerboard version in place of the dagger board.

2. International Moth with removable aluminum and canvas wing section. The rest will be the same.

3. Moth Foiler Ė This will have a wing section and a set of foils

4. The last version will be a club boat for yacht and sailing clubs. We will call it anything a club wants and put their logo on the sail. We will offer either of the moth rigs as an extra so they can travel to our races if they choose to travel.

Contact Information:

Charles Graves

Graves Little Boatyard

1675 Richardson Road

Merritt Island, Florida

32952 U.S.A

Phone: 321-453-6862

Fax: 321-453-8015

Email: ChasMo77@aol.com

WebSite: https://www.angelfire.com/fl2/glb/general.html